The Mixer-settler Extractor

The Mixer-settler Extractor is also called a mixing and clarifying tank. It is a step-by-step contact extraction equipment that relies on gravity to separate two phases. It is mainly composed of a mixing chamber and a clarifying chamber. The raw material liquid and extraction agent first enter the mixing chamber through their respective feed inlets, are mixed and mass-transferred by the agitator, and then enter the clarification chamber through the overflow baffle, where they are naturally separated by gravity. Finally, they enter different outlets to complete the extraction process.

9-level Mixer-settler Extractor

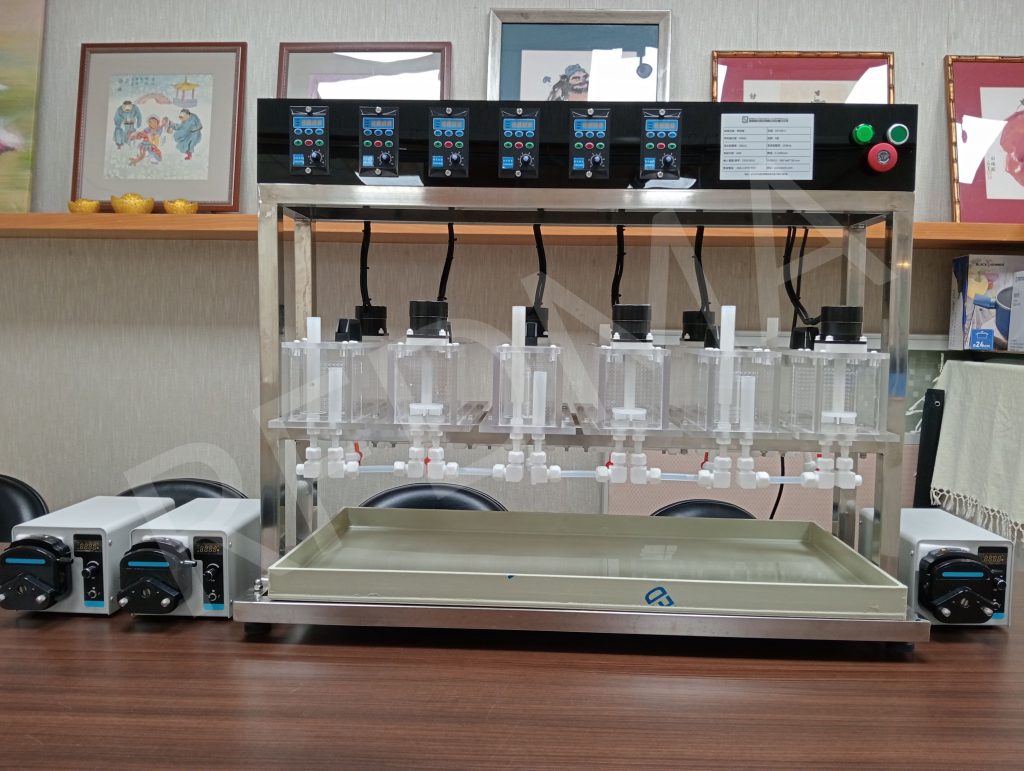

6-level Mixer-settler Extractor

Superiority

Injection molding, no bonding or welding gaps, no risk of leakage.

Simple structure and beautiful appearance.

Free division and combination to easily adjust the test bench.

The materials can be transparent organic glass, translucent PP, PVDF, etc.

Digital speed regulating motor can adjust the speed in time.

Each level is equipped with a sampling hole to facilitate sampling and testing.

A water feed pump is optional to control the amount of water and other liquids.

※Custom-made products (please call or email for inquiries)

54-level Mixer-settler Extractor

Superiority

All extraction tanks will be water sealed to prevent solvent evaporation.

The number of stages of the cascade countercurrent extraction equipment is 54. The height of the water phase at each level is adjustable. Each extraction tank is an independent whole. The bottom of each extraction tank contains the inlet and outlet of the organic phase, the water phase and the current level. Return port.

The cascade extraction tank is made of PVC, a new transparent grade A material.

The inlet and outlet are equipped with quick external thread connectors, and UPVC hard pipes are used to connect the two adjacent stages. The interfaces between the inlet and outlet of the oil phase and water phase of the extraction tank will not loosen or fall off due to the lubrication of the extraction agent.

The metering pump is a flow metering pump that can directly adjust the flow rate. The pipeline uses UPVC pipes and matching PVC directional valves. The metering pump head is made of engineering PVC material, which is acid and alkali resistant and corrosion resistant. The feeding speed is continuously controllable.

The motor controller and speed regulator are both connected to the central control and can be controlled by the integrated operation touch screen or manually adjusted. Each motor is equipped with a digital display speed regulator. The mixing chamber motor can rotate forward and reverse, and the speed is adjustable and controllable. The controller can be integrated in series according to process needs, or can be independently controlled. It is also equipped with an emergency stop switch button.

Each storage tank is equipped with a limit signal light for the upper and lower strokes of the liquid level.

Each stage of extraction, back-extraction, and washing is equipped with pH meter online monitoring, temperature monitoring, and flow dynamic control. Online liquid level monitoring in storage tanks and transfer tanks automatically controls fluid replenishment.

The extraction tank is equipped with a three-layer movable operating platform, which can realize the free movement and combination of metering pumps; the movable platform material is made of welded stainless steel square tubes, with PP lining and no metal exposed outside, and the layer board is made of corrosion-resistant PP material Plate.

An integrated exhaust hood is installed on the upper part of the extraction tank, equipped with a silent duct fan, LED observation light and PP folding air duct.

The 54-level stirring devices are all set on the same side, making it easy to observe phase separation and adjust liquid level control.